You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Making your own CNC cut molds

- Thread starter Killerbug

- Start date

redman

New member

I haven't but know that service is avalible on this side of the big pond. Most of us that do make molds make a blank and press them into soft aluminium. That way we can get a balanced head and custom head to boot. Think that we did have a member who at one time did that work but is no longer doing it. Here is a thread that well documents what we are doing over here. Lots of pictures and detail instructions and even some what not to do's. Enjoy!!!!! http://www.jigcraft.com/jigcraft/showthread.php?tid=2976

Redman

Redman

Ron Don

Future Sponsor

Killerbug most shops won't load the program on their machineunless they wrote the program for fear of a bad file that could screw up the machine!

baitmaster

Moderator

- Joined

- Mar 23, 2010

- Messages

- 262

I did lots of research on building my own 3 axis mill and doing it myself. There are lots of tutorial and plans online. I figured cost of around 500-600 for the mechanical/electrical hardware. Since I do design engineering for a living, I got the CAD/CAM end covered. My only hurdle....time. Family and house barley offer fishing time.

Being curious here with my new position at work and a little more 'weight' in the overall decision making......... Does anyone know what a CNC Mill that could handle custom molds (blank Do-It molds) would costs??? I have the software skills, just not the equipment, but i already run a 2-axis HPGL controller everyday at work and there are some applications we have to turn down (or out source) because we do not have that 3rd axis to make things raised lettering and 3D. If i could sell it to my partner in my business as being cost effective and make a profit, bet i could convince him to invest. What are we looking at as 'needed' tools to create lead molds?

upnort16

New member

I've seen cnc mills as low as $2500.00 but needing many more dollars to bring it up to snuff. A new fully functional one will start at 22,000.00 and up. With all the industry around you and some places closing up, look for sales and auctions. I missed several used but solid machines at the Chrysler auction, so the possibility of you writing software for molds is not that far from reality. Good luck and search hard, I got some ideas, lol.

baitmaster

Moderator

- Joined

- Mar 23, 2010

- Messages

- 262

Here is one of the links I was looking at to build my own. Not sure if the 1/4-20 rod and coupling nut would give enough precision to cut matching molds. Certainly cheaper than a precision cut worm gear. Stepper motors are pretty cheap on eBay.

I priced it all out at around $400.00. Pretty close to the price of a few custom molds

http://m.instructables.com/id/Easy-to-Build-Desk-Top-3-Axis-CNC-Milling-Machine/

I priced it all out at around $400.00. Pretty close to the price of a few custom molds

http://m.instructables.com/id/Easy-to-Build-Desk-Top-3-Axis-CNC-Milling-Machine/

Fatman

Active member

Seems a great way to get a set-up going but it says at the end "Foam, Wood, Plastic and other soft materials" I don't think aluminum blocks fit into that category. Any other info on that????

redear

Active member

you could make a press frame out of iron, buy a car jack, and a drill press and be in business long before you would ever get this accomlished. I'm talking about the molds I built using the press method. and my molds make a better finished head than any other mold I own including a collins custom mold. the only drawback is the press method works better with a round or cylindrical head design, other shapes may move or rock to one side when pressed.

upnort16

New member

One thought I had and finally got the answer for was one of those cnc router carving machines. One of the demonstrators at the woodworking show said yes, it will cut aluminum with the proper tooling. Repetition is not a problem and with careful set-up, I'm certain mirror halves can be machined. I base all this on the fact that the mold designs in my head are all small, perhaps even micro, so there is not major removal of material. I have located cutters as small as 3/32" making fine detail possible. With the design programs an endless stream of ideas can be reality. Protoypes in wood or plastic, then aluminum. Much cheaper than a cnc mill and can be operated in the home shop! All I need now is to justify another machine to the missus and experiment.

Fatman

Active member

Excellent information - now are the molds you want to make already available???

upnort16

New member

Not that I'm aware of, but that don't mean anything. An idea comes and sometimes it's good, sometimes not. I certainly am not a moldmaker to speak of, but have dabbled and made a few. I would like to refine, tune and experiment with a thought or two. I knew a tool and die maker that could machine anything he wanted, all with manual dials, no dro, no cnc. I think if they did it back then, why not now? I've concluded I don't have the know how, experience or patience to, hence the modern gadgets of technology. As of right now, an addition to the shop is a month or two away. I figured since we all have some of the same interests, perhaps a fellow jigcrafter has a cnc router and would like to expand it's usefulness. Who knows? Just tossing it out there.

Fatman

Active member

Well if anyone can be found that can do mold work uncluding pinning eye sockets they would make some money here.

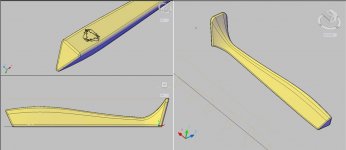

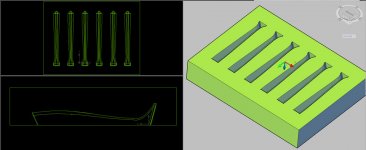

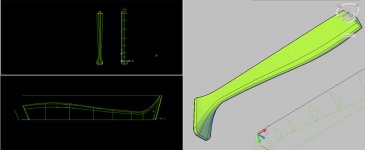

Hi, I got somehow further with the Digital Prototyping of a swimbait, and the construction of a mold for it.

http://forum.esoxhunt.dk/viewtopic.php?f=69&t=878&p=5232#p5232

http://forum.esoxhunt.dk/viewtopic.php?f=69&t=878&p=5232#p5232

Fatman

Active member

Site comes up but not the attachments - You have to be a member to get them. Can you copy them to your system then attach to here

Sure, I have attached my latest creations. One mold for top pouring, and one for injection. If anyone have experience in CNC mold making, I would love to hear from them, about prices etc.

Attachments

Fatman

Active member

Don't know if Jacobs' baits would do it but you could email him http://stores.jacobsbaits.com/-strse-template/about/Page.bok

Check out his site he may have what your're looking for already made. As you can see we have the same problems in getting molds done here - kinda have to go with what's out there and modify them if we can without screwing them up

Check out his site he may have what your're looking for already made. As you can see we have the same problems in getting molds done here - kinda have to go with what's out there and modify them if we can without screwing them up

SnakeRiver here had posted a little while back where the Jacobs' Baits place was creating custom plastic molds for people - had a forum for it and all - but now the link is dead. ( http://www.jigcraft.com/jigcraft/showthread.php?tid=4833 )

Fatman said:Don't know if Jacobs' baits would do it but you could email him http://stores.jacobsbaits.com/-strse-template/about/Page.bok

Ron Don

Future Sponsor

Killerbug I will pm you some info tonight. I have used all the plastic mold makers and can give you firsthand info!!!

Ive made my own mold on manual mills and cnc mills, but all by hand programming every line of code.

Your probably not going to get it done any cheaper weather you or they program your mold. They still have to set up the machine and tooling to your zero where ever that may be and if you accidently goofed up on a line of code, their machine crashes. And i dont mean opps i broke a bit. They have to run the progran first in slow mode to check for problems.

Your probably not going to get it done any cheaper weather you or they program your mold. They still have to set up the machine and tooling to your zero where ever that may be and if you accidently goofed up on a line of code, their machine crashes. And i dont mean opps i broke a bit. They have to run the progran first in slow mode to check for problems.